Double Pig System Working Principle: Enhancing Efficiency in Pipeline Operations

The double pig system is a specialized tool used in pipeline maintenance to optimize cleaning, inspection, and product separation processes. Understanding its working principle is crucial for effectively managing pipeline assets and ensuring operational efficiency.

Introduction to the Double Pig System

The double pig system integrates two pigs, or pipeline inspection gauges, within a single operational setup. Pigs are devices inserted into pipelines to perform essential tasks such as cleaning debris, inspecting pipeline walls for defects, and optimizing flow conditions. This system enhances efficiency by enabling double pig system working principle simultaneous cleaning and inspection operations, thereby minimizing downtime and maintaining pipeline integrity effectively.

Components of the Double Pig System

- Cleaning Pigs:

- One component of the double pig system is dedicated to cleaning the pipeline. Cleaning pigs typically have brushes or scrapers that remove debris, scale, and deposits from the inner walls of the pipeline.

- The primary function of cleaning pigs is to improve flow efficiency, prevent corrosion, and maintain the cleanliness of the pipeline.

- Inspection Pigs:

- The second component is an inspection pig equipped with advanced technologies such as magnetic flux leakage (MFL), ultrasonic testing, or caliper tools.

- Inspection pigs assess the integrity of the pipeline by detecting defects, measuring wall thickness, and identifying potential areas of concern such as corrosion or cracks.

Read also: Thriving in Tech: Staying Relevant in an Evolving Industry

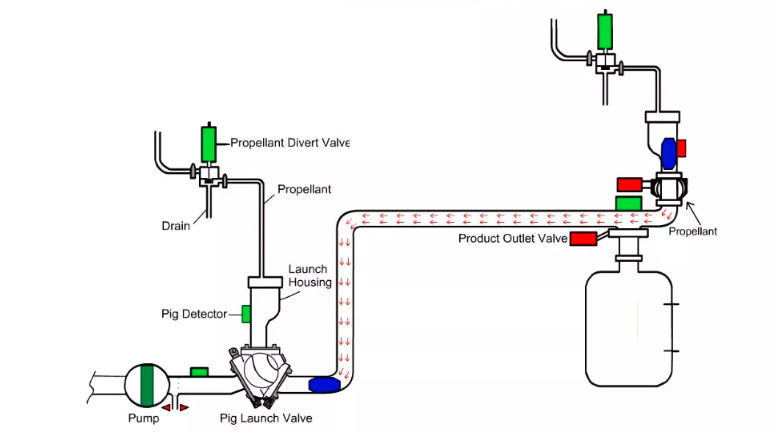

Working Principle of the Double Pig System

- Launching and Propulsion:

- The double pig system begins with the launching of two pigs into the pipeline through a launcher. The launcher seals the pipeline and provides a mechanism for safely inserting the pigs into the flow stream.

- Depending on the design and operational requirements, pigs may be propelled through the pipeline using product flow (flow-assisted pigging) or driven by external means such as compressed air or hydraulic pressure.

- Simultaneous Operation:

- Once launched, the cleaning pig and inspection pig travel through the pipeline simultaneously. The cleaning pig moves ahead, scraping and removing debris from the pipeline walls.

- Following closely behind, the inspection pig performs its functions, collecting data on the condition of the pipeline and transmitting this information to monitoring systems or operators.

- Data Collection and Analysis:

- As the pigs traverse the pipeline, sensors and measurement devices on the inspection pig capture data related to wall thickness, defects, and anomalies.

- This data is analyzed in real-time or post-operation to assess the integrity of the pipeline, identify maintenance needs, and plan future operations.

- Retrieval and Analysis:

- At the end of the pipeline, the pigs enter a receiver where they are safely retrieved. The receiver typically includes traps to collect debris removed by the cleaning pig and ensure it does not re-enter the pipeline.

- Inspection data collected by the pigs is reviewed and analyzed to generate reports, assess pipeline condition, and inform decision-making regarding maintenance and operational improvements.

Benefits of the Double Pig System

- Efficient Maintenance: Simultaneous cleaning and inspection operations reduce downtime and optimize pipeline maintenance schedules.

- Enhanced Safety: Regular inspections and cleaning mitigate the risk of leaks, ensuring safe operation and compliance with regulatory standards.

- Cost Savings: Preventive maintenance reduces repair costs and extends the lifespan of pipeline assets, maximizing return on investment.

- Operational Efficiency: By performing multiple tasks in a single operation, the double pig system improves workflow and operational efficiency.

Considerations for Implementation

- Pipeline Compatibility: Ensure the double pig system is compatible with pipeline dimensions, materials, and operational conditions.

- Training and Maintenance: Proper training of personnel in double pig system operations and maintenance is crucial for safe and effective use.

- Technological Advancements: Stay informed about advancements in pigging technology to enhance operational capabilities and data-driven decision-making.

Conclusion

The working principle of the double pig system underscores its importance in optimizing pipeline maintenance and efficiency. By integrating simultaneous cleaning and inspection capabilities, industries can effectively manage pipeline assets, ensure regulatory compliance, and maximize operational performance. As technology continues to advance, the double pig system remains a valuable tool for enhancing pipeline integrity and sustainability across various industrial applications.