What Is a Heat Sink and How Does It Work? Explained

If you’ve ever wondered what is a heat sink , it’s essentially a device that keeps electronic components from overheating by absorbing and dispersing heat. From CPUs and GPUs in your computer to LEDs and power electronics, heat sinks play a critical role in maintaining performance and extending the lifespan of devices.

By using materials like aluminum or copper, a heat sink efficiently transfers heat away from sensitive parts, preventing damage and ensuring stability. In this article, we’ll explore the basics of how heat sinks function, why they’re so important, and where you’re most likely to find them.

What Is a Heat Sink?

A heat sink is a key component in electronic devices that prevents overheating by absorbing and removing excess heat from components like processors or chips. It works as a passive cooling system, transferring heat from the component into the heat sink and then releasing it into the surrounding air.

How a Heat Sink Works

- Heat Transfer from the Source

Electronic parts like CPUs or GPUs generate heat while operating. This heat moves into the heat sink through direct contact or using a thermal interface material (like thermal paste). Heat sinks are usually made of metals like aluminum or copper, which conduct heat well.

- Conduction Within the Heat Sink

Once heat enters the heat sink, it spreads through the metal from the base to the fins or other extended surfaces. This movement follows the natural flow from hotter to cooler areas.

- Heat Dissipation via Convection and Radiation

The fins or extended surfaces of the heat sink increase its contact with air, helping heat escape efficiently. Air carries the heat away through convection, and a small amount is also released as radiation. Fans or liquid cooling can further improve airflow and cooling.

Why Heat Sinks Are Important

- Prevent Overheating: Stops components from getting too hot and slows down.

- Enhance Reliability: Keeps components at stable temperatures for consistent performance.

- Extend Lifespan: Reduces thermal stress and helps devices last longer.

Heat sinks are essential for keeping electronic devices cool, reliable, and long-lasting.

Types of Heat Sinks

Heat sinks are essential for keeping electronic components cool and can be grouped into three main types: active, passive, and hybrid.

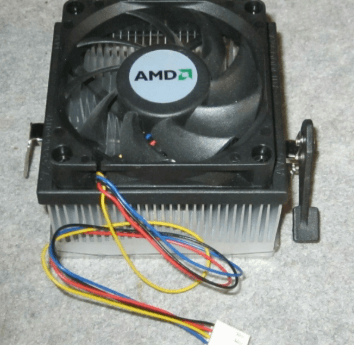

- Active Heat Sinks

Active heat sinks utilize powered components such as fans or liquid cooling systems to efficiently transfer heat away from electronic parts. They are typically used in high-performance devices like gaming PCs, servers, and powerful CPUs or GPUs that produce a lot of heat during use.

- How they work: The fans or pumps push air or liquid over the heat sink, helping to remove heat faster and maintain stable temperatures.

- Advantages: Deliver faster, more consistent cooling. Perfect for high-heat systems.

- Disadvantages: Can be noisy, consume more power, and require more complex installation or maintenance.

- Passive Heat Sinks

Passive heat sinks don’t use any moving parts. Instead, they rely on natural airflow and conduction to remove heat. These are often found in smaller, low-power devices such as smartphones, IoT gadgets, or LED lighting systems.

- How they work: Heat moves from the component into the heat sink and then into the air naturally.

- Advantages: Silent operation and high reliability since there are no moving parts that can fail.

- Disadvantages: Less effective in high-heat situations or where airflow is limited.

- Hybrid Heat Sinks

Hybrid heat sinks combine both active and passive cooling methods. They might include fans or pumps along with large fins or special materials that increase heat dissipation.

- How they work: Hybrid heat sinks combine natural airflow and fans to cool components efficiently while producing less noise than fully active systems.

- Advantages: Hybrid heat sinks provide strong cooling while running quieter than fully active systems.

- Disadvantages: More expensive and complex to manufacture and maintain, with a higher risk of failure if active parts stop working.

Active heat sinks offer powerful cooling, passive ones are quiet and energy-efficient, and hybrid designs combine both benefits. The right choice depends on the device’s power, heat output, and cooling needs.

Materials and Design Considerations

Heat sinks are usually made from aluminum or copper because both metals conduct heat very well. Each material has its own advantages and trade-offs, depending on the cooling needs of the device.

Aluminum

- Lightweight and affordable – Easier to produce and install, making it cost-effective.

- Good thermal conductivity – Conducts heat well enough for most applications.

- Best for: Devices where weight and cost are important, such as laptops, consumer electronics, or LED systems.

Copper

- Excellent heat conductor – Transfers heat about twice as efficiently as aluminum.

- Drawbacks: Heavier, more expensive, and harder to shape.

- Best for: High-performance systems that need maximum cooling efficiency, such as CPUs, GPUs, and servers.

Modern Design Improvements

Recent improvements in heat sink technology focus on making cooling systems work better and use energy more efficiently. These include:

- Composite materials – Combine metals or add coatings to improve heat transfer and reduce weight.

- Vapor chambers and heat pipes – Spread heat evenly across the heat sink surface.

- Enhanced fin designs – Increase surface area to allow better airflow and faster heat dissipation.

Choosing the right material and design depends on the balance between performance, cost, weight, and space. While copper provides superior cooling, aluminum remains the go-to choice for most applications due to its light weight and affordability.

Common Applications of Heat Sinks

Heat sinks are essential for keeping electronic components cool, ensuring they work efficiently and last longer. They are used across many industries.

- Computers: CPUs, GPUs, and VRMs

Heat sinks cool central processing units, graphics cards, and voltage regulator modules, which generate a lot of heat during operation. By keeping temperatures under control, heat sinks prevent performance slowdowns and component damage. Aluminum and copper are commonly used because they conduct heat well.

- LEDs and Lighting Systems

LEDs and other lights produce heat that can reduce brightness and shorten lifespan. Heat sinks help release this heat, keeping lights bright, efficient, and long-lasting.

- Power Electronics and Automotive Systems

High-load devices like inverters, converters, and automotive electronics generate significant heat. Heat sinks prevent overheating, protecting systems from failure and ensuring reliable operation.

- Renewable Energy Systems

Solar and wind power systems use heat sinks in inverters and converters to manage heat during energy conversion. Proper cooling keeps these systems efficient and extends their lifespan.

Why Heat Sinks Are Important

Heat sinks are vital in modern electronics because they manage heat and protect sensitive components from damage. Here’s why they’re so important:

- Prevent Overheating and Damage

Heat sinks absorb and remove excess heat from electronic components, keeping them at safe temperatures and preventing overheating, performance slowdowns, or permanent damage.

- Maintain Stable Performance

Electronic components perform optimally within certain temperature ranges. Heat sinks keep these components cool, ensuring consistent performance and reducing the risk of errors, crashes, or slowdowns during heavy use.

- Extend Device Lifespan

Excessive heat shortens the lifespan of electronic components. Heat sinks reduce thermal stress, allowing devices to run longer and minimizing the need for repairs or replacements.

- Quiet and Energy-Efficient Cooling

Many heat sinks cool devices without fans or pumps, making them both silent and energy-efficient. This makes them ideal for environments where low noise and reduced power consumption are important.