Jobsite’s Silent Guardians: How Compliance Plates Promote Construction Safety

How can construction companies ensure that all equipment and machinery on-site meet the required safety standards? Construction sites are bustling environments where safety is paramount. Workers rely on various safety measures and protocols to ensure their well-being while performing potentially hazardous tasks. Ensuring that every machinery and equipment complies with safety regulations is complex.

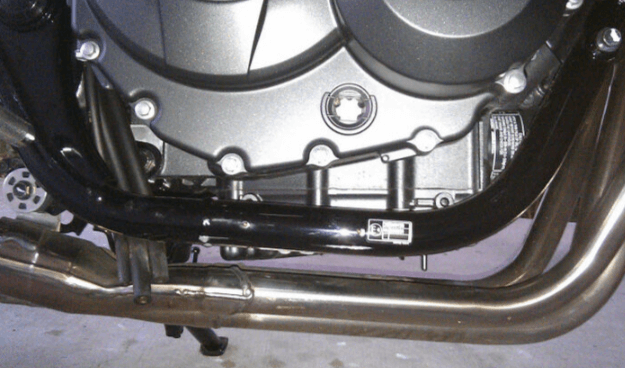

This is where a compliance plate plays a crucial role and is a vital component in maintaining construction safety standards. These metal tags or labels are attached to machinery and equipment, providing essential information about the item’s compliance. Moreover, they help workers and inspectors verify that all machinery is safe to use, ensuring adherence to regulations.

Ensuring Equipment Safety

Equipment safety is a top priority in construction. Without proper measures, construction sites can become dangerous places. The information on these tags helps prevent accidents by providing crucial details about the machinery. Knowing the specifications and compliance details allows operators to use the equipment correctly and safely.

- Manufacturer Information: The compliance tag includes the manufacturer’s name and model number, ensuring traceability and accountability.

- Safety Standards: It lists the specific standards the equipment adheres to, ensuring it meets regulatory requirements.

- Maintenance Records: These tags often include information about maintenance schedules and service records, ensuring regular upkeep.

Regulatory Compliance

Construction is a highly regulated industry with stringent standards. Compliance tags help companies effortlessly meet these regulations. They prove the equipment has been manufactured and maintained according to legal requirements.

- Inspection Readiness: During inspections, the presence of these tags helps quickly verify compliance, saving time and ensuring smooth operations.

- Legal Protection: They provide legal protection in case of accidents, proving that all necessary measures are in place.

- Standardisation: These tags ensure a standardised approach to safety across different sites and projects.

Enhancing Worker Safety

The information these tags provide ensures workers know the equipment’s capabilities and limitations. It also prevents the misuse of machinery, a common cause of workplace accidents.

- User Awareness: Compliance tags educate workers about the equipment, making them aware of its specifications and safe operating procedures.

- Preventive Measures: Knowing the maintenance records helps identify potential issues before they lead to accidents.

- Training: These tags are often used during training sessions to teach workers about proper equipment usage.

Read also Maximize Your Savings with Canara and Axis Bank FD Calculators

Supporting Efficient Operations

Any delay due to equipment failure or issues can be costly. Compliance tags contribute to smoother operations by ensuring all equipment is safe and operational. They reduce downtime caused by equipment checks, as the necessary information is readily available.

- Quick Verification: Equipment checks are faster and more efficient with the necessary compliance information

- Reduced Downtime: Regular maintenance information helps schedule preventive maintenance, reducing unexpected breakdowns.

- Operational Continuity: Ensuring all equipment is compliant and safe to use helps in maintaining continuous operations without safety-related interruption

Improving Accountability and Traceability

They also significantly improve accountability and traceability on construction sites. Detailed information about each piece of equipment ensures that every tool and machine can be tracked and monitored effectively.

- Traceability: The unique identifiers on compliance tags make it easy to trace the history of the equipment, including its origin, usage, and maintenance.

- Accountability: With clear information on the tags, it becomes easier to hold manufacturers and operators accountable for the equipment’s condition and safety.

- Inventory Management: These tags assist inventory management by providing detailed records of all equipment and helping track usage, maintenance schedules, and replacement needs.

A compliance plate may be monorail, but its role in construction safety is undeniable. These small labels act as silent guardians, promoting worker awareness, facilitating communication, and ensuring regulatory compliance. By incorporating them into their safety protocols, construction businesses can create a safer work environment for everyone involved, ultimately paving the way for a successful and accident-free project.